Apple began its relationship with India back in 2017 when Foxconn set up their manufacturing plant at Sriperumbudur on the outskirts of Chennai.

Fast forward to today and Apple has assembled the SE, iPhone 12, iPhone 13 and even the new iPhone 14 from a total of 3 plants in India. But are they planning on moving their entire manufacturing process out of China and if so will India be a good choice in terms of market and output numbers?

Reports suggest that Apple plans to turn India into their iPhone global manufacturing hub by 2025 and are slowly reducing its dependence on China.

They currently have three plants set up in India, Foxconn Pegatron and Wistron which have collectively been able to manufacture and ship out over a million iPhone’s in just the first quarter of 2022 and this is just the beginning.

According to a report in September 2022, JP Morgan analysts predicted that Apple would move 5% of their iPhone 14 production line to India in late 2022 and are looking to have at least 25% of all iPhone’s to be made in India as early as 2025 with numbers touching as high as 50% by 2027.

Let’s take a look at all the possible outcomes and see if India is a great option for Apple as its manufacturing hub and will iPhone be made in India in the near future.

Will iPhone be Made in India in the Future?

Table of Contents

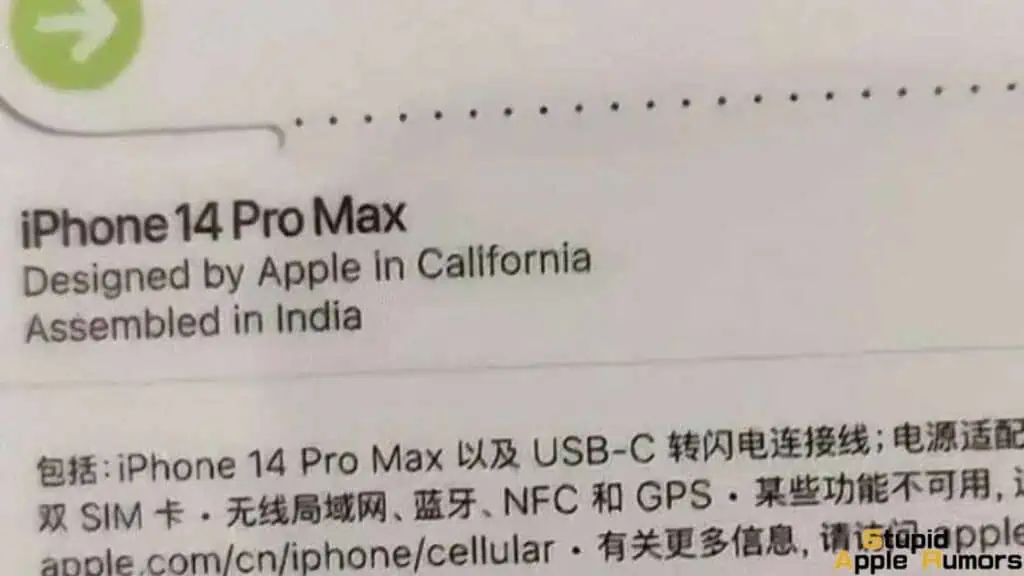

Hardly 3 weeks after the new iPhone 14 launched, Apple announced that they will be moving their production line to India where the new iPhone 14 will be manufactured and assembled.

The Cupertino tech giant also informed the world that these “Made in India” iPhones are not just for the domestic Indian market but will also be exported abroad to countries like the U.S and Canada. In fact, many buyers around the world have already started receiving “Made in India” iPhones.

Analysts estimate that due to the rising hostile relationship between the U.S and China, Apple may shift their global manufacturing hub to India as soon as 2025 and we’re expected to witness a year on year manufacturing growth of up to 200%.

According to a report from Counterpoint Research, only 23% of iPhone shipments in India for 2022 were imported whereas the rest were produced locally and with India being the second largest smartphone market in the world, it’s only fitting that Apple increases their presence and sales in this South Asian country.

In order to do that they need to have a robust system in place alongside a solid manufacturing plant situated within India.

Does India Have What It Takes to Manufacture iPhone’s?

Well yes, India has always had a lot to offer Apple, with their young and energetic population, a growing market and relatively low employment costs.

This is the primary reason why Apple has been working closely with the Indian government to establish India as a centralized hub for manufacturing iPhones.

Not only will this move help boost the Indian economy but Apple will also be able to ship finished iPhones to their customers without any hiccup or delay in the production line, something that has been a recurring problem with their China plants post the Covid breakout.

The only thing lacking in India is a sound infrastructure and since most of the suppliers are still based in China, procuring components for iPhone’s can prove to be a costly affair because of which we may not witness a significant drop in the price of made in India iPhone’s anytime soon.

What Does This Move Mean for India?

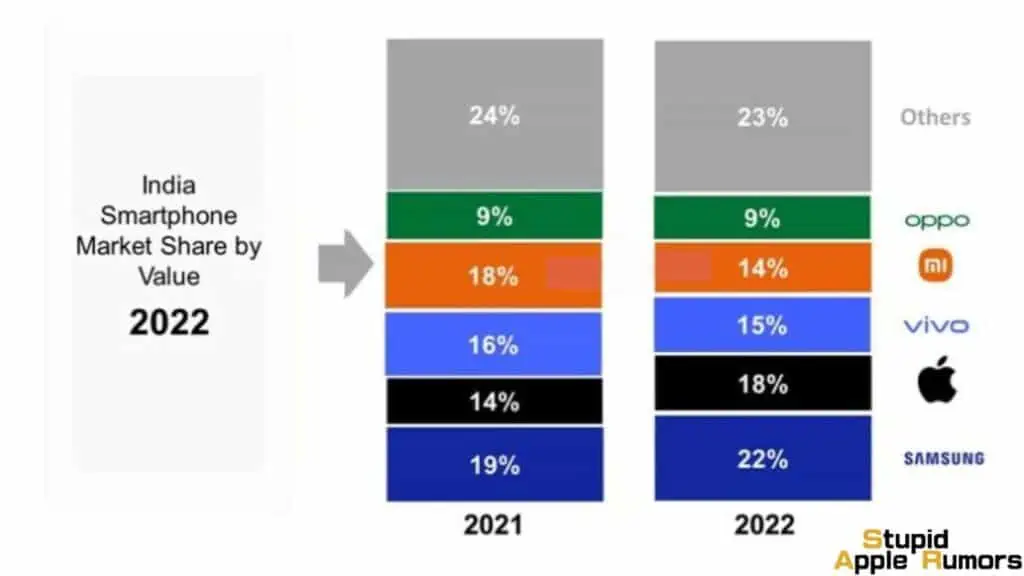

Apple’s growth in India is being driven by a rapidly expanding middle class and increasing disposable incomes, which has led to a surge in demand for premium smartphones. The Indian smartphone market is also becoming increasingly competitive, with a number of domestic and international players vying for market share.

Apple has responded to this growing demand by introducing new, more affordable models, such as the iPhone SE, aimed specifically at the Indian market. The company has also invested in local production, setting up a manufacturing facility in the country and working with local suppliers to increase its presence.

This increased production and presence in India has also allowed Apple to reduce its dependence on China as a manufacturing hub, which has become increasingly important in the wake of U.S.-China trade tensions.

The growth of the iPhone market in India is expected to have a significant impact on the tech industry and the Indian economy. It is also expected to encourage other smartphone manufacturers to enter the market and increase competition, leading to a wider range of options for consumers and potentially lower prices.

In fact, Indian brand Tata is already in talks with Apple’s Taiwan based partners to support the local supply chain and they are keen on buying shares in Wistron for product development and assembly of iPhone’s within India.

This partnership might signal a drastic increase in the production output of iPhone’s by 5 times according to a report in Bloomberg.

Apple is Slowly Cutting Their Dependence on China

In recent years, the U.S. – China trade tensions have created an uncertain business environment for companies relying on Chinese manufacturing, and Apple is no exception.

By reducing its dependence on China, the company hopes to mitigate the potential impact of any tariffs or trade restrictions that may be imposed in the future.

Additionally, the rising labor costs in China have also been a concern for Apple and other multinational companies operating in the country. By diversifying its supply chain, the company aims to reduce its reliance on a single country and lower its manufacturing costs.

As part of this effort, Apple has been ramping up its production in other countries such as India and Vietnam. The company has reportedly invested in local suppliers and manufacturers in these countries to increase its presence and reduce its dependence on China.

This move by Apple to reduce its dependence on China is expected to have far-reaching implications for the tech industry, particularly for companies that rely heavily on Chinese manufacturing.

It highlights the need for companies to be flexible and adaptable in a rapidly changing global environment and to have contingency plans in place to mitigate risk.

Is Apple Following a Trend by Picking India as its Manufacturing Hub?

In recent years, a number of MNC’s including Apple have been seeking to diversify their supply chains and reduce their dependence on China.

India has emerged as a popular alternative for companies such as Samsung and Google looking to tap into the growing middle class and reduce their exposure to geopolitical risk.

The Cupertino tech giant has reportedly invested in local suppliers and manufacturers to increase its presence in the country and manufacture more of its products locally.

According to South China Morning post, Apple’s biggest contractor Foxconn has reportedly invested nearly $500 million in its Indian subsidiary and are planning to diversify its supply chain into India.

This move by Apple has been seen by some as following a trend, as other tech companies such as Xiaomi have also set up manufacturing facilities in India.

However, others argue that Apple is leading the way, setting an example for other companies and paving the way for further investment in the country.

Apple’s Long Term Goal in India

Apple’s long-term goal in India is to establish a strong presence in the country and tap into its massive market potential.

The company’s investment in local manufacturing and retail operations is expected to benefit the Indian economy and create job opportunities, while also promoting technological innovation and development.

Apple is also exploring the possibility of setting up retail stores in the country, a move that will allow it to reach out to a larger audience and increase brand awareness. The Indian government has shown a keen interest in attracting Apple to set up their base of operations in the country.

In a recent statement, the country’s commerce and industry minister, Piyush Goyal said that “the government is keen to facilitate Apple’s investment in India and would provide all necessary support to the company.”

The company’s investment in local manufacturing and retail operations is likely to benefit local suppliers and partners, thereby promoting the development of local businesses, something that aligns with the “Make in India” initiative which Prime Minister Narendra Modi has been pushing for over the last few years.

In fact, Apple is currently manufacturing and assembling iPhone’s out of three plants, Wistron in Bangalore, Pegatron and Foxconn in Tamil Nadu where Pegatron handles the manufacturing of the iPhone 12 whereas Foxconn looks after the iPhone 11, iPhone 12, iPhone 13 and the latest iPhone 14.

What Does the Future of Made in India iPhone’s Look Like?

The increasing demand for smartphones in India, coupled with the government’s favorable policies, makes India an attractive market for smartphone manufacturers.

Apple has already started manufacturing a few models of iPhones in India through its partner, Foxconn. The company is expected to expand its manufacturing operations in India in the coming years and not just assemble iPhones in the country.

The production of iPhones in India not only reduces the cost of manufacturing, but also helps Apple to avoid import duties, making their products more affordable for Indian customers.

Moreover, the Indian government’s recent changes to foreign direct investment (FDI) policies in the e-commerce sector will also benefit companies like Apple. This will make it easier for Apple to sell its products online in India, increasing their reach to customers across the country.

However, there are also some challenges that Apple may face in India. For example, the intense competition from local and global players, the relatively lower purchasing power of Indian consumers, and the country’s complex regulatory environment are some of the challenges that Apple may have to overcome in the coming months.

It’s important to note that Apple is truly making an effort to capitalize on the PLI scheme in India where they are expected to manufacture iPhone’s worth roughly 47,000 crores in the financial year 2023 which looks to be a 5-fold increase from what their numbers were last year.

How Long Will it Take for Apple to Move its Supply Chain to India?

Apple’s plan to move a significant portion of its supply chain out of China and into India is expected to take several years to fully implement.

However, the impact of this shift is already being felt across the tech industry and beyond. The move is seen as a major win for India, which has been actively courting multinational corporations looking to diversify their production base away from China.

One of the biggest benefits for Indians looking to purchase a new “Made in India” iPhone will be the reduced cost. With lower labor costs and favorable government policies, it is expected that the cost of manufacturing the iPhone in India will be significantly lower than in China.

This reduction in cost is expected to be reflected in the price of the iPhone for consumers in India, making it more accessible to a wider audience.

What’s in Store for 2023?

According to a report from Bloomberg, Apple will move a total of 5% of their production volume to India by Spring 2023 and over time Foxconn, Pegatron and Wistron will increase that number to 20%, however no timeline was shared on when this would take effect.

It’s also reported that the trial production of the iPhone 15 has commenced in the HonHai’s Shenzhen Guanlan factory in China and they have entered the NPI process to work out how long it would take to manufacture and assemble the iPhone 15.

India currently is 6-9 weeks slower than China in terms of production, but if Apple is able to shrink the time it takes to perform NPI in India to a couple of weeks then we can expect the production of iPhone’s in India to double and even triple in volume.

The problem with NPI in India is that there’s no streamlined process in place and if Apple wants to see a quicker turnaround then they will have to establish controls to maintain confidentiality with Indian manufacturers.

Also Read:

- 2023 iPhone 15? | All the News and Rumors So Far

- Apple Rumored to be Testing a Version of macOS for the M2 iPad Pro

Alan Urban is the Editor-in-chief of Stupid Apple Rumours and often proclaims that he’s ” Apple’s number one fan.”

In addition to keeping up with the latest Apple news, he also reviews Apple products and creates user-friendly guides. When not subjecting Apple Devices to crazy stress tests, he’s usually playing games on Apple Arcade